Wire Rope

How do you choose the best wire rope for your application?

While for many jobs the answer may be simple, the correct choice often requires knowledge and experience.

Our sales and customer service staff is willing and able to assist you in finding the right rope for your application.

To assure you of the highest quality product and engineering, American Rigger’s Supply represents WireCo WorldGroup products. Wire rope design, manufacture and use are highly specialized fields and that is why we rely on their unsurpassed technical support.

No single rope can do it all.

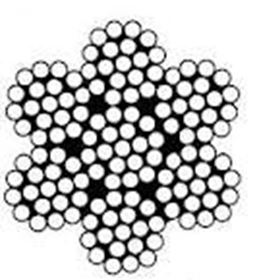

All wire ropes feature design characteristic tradeoffs. For example, when you increase fatigue resistance by selecting a rope with more wires, the rope will have less abrasion resistance because of its greater number of smaller outside wires.

The Seven Design Characteristics of Wire Rope

- Strength

Wire rope strength is generally measured in U.S. tons (2,000 lbs.). In published material, wire rope strength is shown as “nominal strength. Nominal strength refers to calculated strength figures that have been accepted by the wire rope industry. The nominal strength applies to new, unused rope. A rope should never operate at or near the nominal strength. -

Fatigue resistance

Fatigue resistance involves metal fatigue of the wires that make up the rope. To have high resistance, wires must be capable of bending repeatedly under stress, for example, a rope passing over a sheave. Increased fatigue resistance is achieved in a rope design by using a larger number of wires. It involves both the basic metallurgy and the diameters of wires. -

Crushing resistance

Crushing is the effect of external pressure on a rope, which damages it by distorting the cross-section shape of the rope, its strands or core - or all three. Crushing resistance therefore is a rope’s ability to withstand or resist external forces and is term generally used to express comparison between ropes. -

Resistance to metal loss and deformation

Metal loss refers to the actual wearing away of metal from the outer wires of a rope, and metal deformation is the changing of the shape of the outer wires of the rope. In general, resistance to metal loss by abrasion (usually called “abrasion resistance”) refers to a rope’s ability to withstand metal being worn away along its exterior. The most common form of metal deformation is generally called “peening”. Outside wires of a peened rope appear to have been hammered along their exposed surface. Peening usually occurs on drums, caused by rope-to-rope contact during spooling of the rope on the drum. It can also occur on sheaves. - Stability

The word “stability” is most often used to describe handling and working characteristics of a rope. It is not a precise term since the idea is expressed to some degree as a matter of opinion. For example, a rope is called stable when it spools smoothly on and off a drum or doesn’t tangle when a multi-part reeving system is relaxed. - Bendability

Bendability relates to the ability of a rope to bend easily in an arc. Four primary factors affect this capability:

1. Diameters of wires that make up the rope

2. Rope and strand construction

3. Metal composition of wires and finish

4. Type of rope core.Some rope constructions are by nature more bendable than others. Small ropes are more bendable than large ones. As a general rule, ropes of many wires are more bendable than ropes made with fewer, larger wires.

- Reserve strength

Reserve strength of a rope is the percentage of its catalog strength which is represented by its inner wires. This recognizes that outer wires should be the first to be damaged or worn away. Usually, the more wires there are in each strand of rope, the greater will be its reserve strength. Reserve strength is especially important in selecting a rope for use where consequences of rope failure are great

Please allow us to assist you by giving us a call. We would be happy to hear from you.

800-952-8658