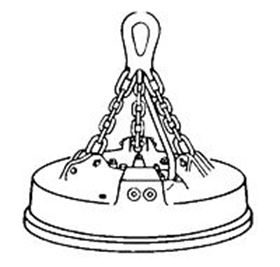

Alloy Chain Slings

We offer a complete selection of Alloy Chain Slings to meet your lifting needs.

When selecting the proper sling for your application, please allow our experienced staff to assist you in choosing the right type.

Alloy chain slings are often the choice for rugged and abusive environments. However, many customers find they work well in light weight and moderate applications. In addition to a wide variety of standard hooks and attachments we offer custom designs to meet your specific requirements.

Advantages

-

Steel construction resists abrasion and cutting

-

Flexible for gripping the contours of the load and ease of storage

-

Durable metal tag stamped with capacity and serial number

-

No loss of capacity up to 400 degrees F and can be used at temperatures up to 1000 degrees F (please ask for assistance in determining capacities above 400)

-

Easily made adjustable in length

-

Repairable

-

Stainless steel is available in some sizes for hotter or corrosive environments

Inspection Criteria for Alloy Chain Slings

Remove the sling from service if any of the following is visible.

-

Missing or illegible sling identification

-

Cracks or breaks

-

Stretched chain links or components

-

Bent, twisted, or deformed chain links or components

-

Evidence of heat damage

-

Excessive pitting or corrosion

-

Lack of ability of chain or components to hinge (articulate) freely

-

Weld splatter

-

Opened or bent hooks

-

Damaged rigging hardware

-

Other conditions, including visible damage, that cause doubt as to the continued use of the sling

Repairs

If your alloy chain slings are in need of repair, we will gladly inspect them and offer you an estimate for repair and testing.